Other Product $22

In condimentum facilisis porta. Sed nec diam eu diam mattis viverra. Nulla fringilla, orci ac euismod semper, magna diam.

Buy Now

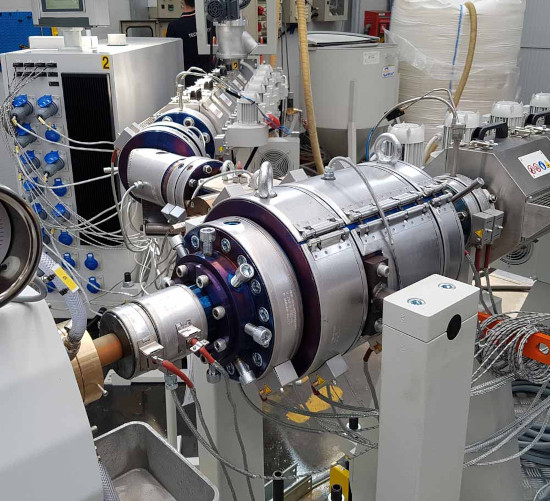

Injection and extrusion systems

Laboratory equipment

Water dispenser

Screw / bronze pins / Bipolar connectors / ceramic block / cables

Extruders 0,5 Watts/cm2 to 3 Watts/cm2

Injection 0,5 to 5 Watts/cm2

Ask technical department for others densities

Several models need an extra sheeet for aditional protection and extra force clamp of the unit.

Made with bronze tubes, inside fit the mica coil

Very useful in nozzles were leackage of plastic is common

Always exit cables at 180°

The ideal solution when only a limited clearance is available between nozzle and mould (e.g. in hot-chamber moulds)

In addition, they are characterised by a high specific power (5 W/cm2) and, consequently, are best suited whenever the heat demand in the injection area needs to be increased.

Finally, thanks to the employ of stainless steel in the external sheath, these heaters are recommended whenever the melted plastic materials is corrosive (PVC and others).

These heaters are employed in all the plastic moulding machines where the operational temperature does not exceed 350°C.

There are areas where for safety reasons it is not acceptable to have exposed screws.

In other places, it is necessary to have connection systems that allow for quick replacement of elements.

To address these situations, there are single-pole bushing outputs.

These consist of a brass piece that protects the electrical connection.

This type of connection is complemented by single-pole ceramic or silicone plugs, which allow for the disconnection of the heating band without cutting off the power or stopping the production process.

This type of outlet is very useful in the case of nozzle-type outlets, where the injection machine advances so deep into the support plate that it makes it impossible to exit the screws, and in the case of outlets with cable outlets, due to their flexibility they end up touching the cast plate and are damaged by friction.

The outlet with a remote terminal block provides a solution to all these problems, since the maintenance operator can give the outlet its final shape before the nozzle of the injection machine advances to the working position.

In condimentum facilisis porta. Sed nec diam eu diam mattis viverra. Nulla fringilla, orci ac euismod semper, magna diam.

Buy Now

In condimentum facilisis porta. Sed nec diam eu diam mattis viverra. Nulla fringilla, orci ac euismod semper, magna diam.

Buy Now

In condimentum facilisis porta. Sed nec diam eu diam mattis viverra. Nulla fringilla, orci ac euismod semper, magna diam.

Buy Now

In condimentum facilisis porta. Sed nec diam eu diam mattis viverra. Nulla fringilla, orci ac euismod semper, magna diam.

Buy Now

In condimentum facilisis porta. Sed nec diam eu diam mattis viverra. Nulla fringilla, orci ac euismod semper, magna diam.

Buy Now